Sections

- Advantages of biological wastewater treatments

- Aerobic systems

- Classification of aerobic digestion reactors

- Aerobic vs. anaerobic reactors

- Sludge management

Advantages of biological wastewater treatments

Biological wastewater treatment (anaerobic and aerobic digestion reactors) takes advantage of the ability of certain microorganisms (including bacteria) to assimilate organic matter and nutrients dissolved in the water for their own growth, thus removing soluble components in the water. Soluble organic matter is assimilated by microorganisms as a carbon source. After this operation, the biomass produced from the supernatant is then separated by decantation. For microorganisms to grow, nitrogen and phosphorus are needed in the effluent as well as organic matter. If their concentration is not sufficient, they have to be added to the treatment.

The traditional application consists of removing biodegradable organic matter, both soluble and colloidal, and compounds containing nitrogen and phosphorus. It is one of the most common treatments for urban wastewater and most industrial water, due to its simplicity and low operating economic cost.

In most cases, the organic matter constitutes the energy and carbon source that the microorganisms need in order to grow. The presence of nutrients that contain the essential elements for growth is also necessary, especially the compounds N and P, and finally, in the case of an aerobic system, the presence of oxygen dissolved in the water. This final aspect is key when choosing the most suitable biological process.

The only requirements for the successful application of these technologies are that the contamination is biodegradable and that there are no biocidal compounds in the effluent to be treated. Microorganisms can assimilate organic matter either with or without the presence of oxygen.

In the bacterial metabolism, the electron acceptor element plays a fundamental role in the processes of oxidation of the organic matter. In addition, this aspect has an important impact on the application options of the water treatment. On the basis of said electron acceptor, three cases are distinguished:

- Aerobic systems: The presence of O2 makes this element the electron acceptor, which is why elevated energetic outputs are obtained, causing an important generation of mud due to the high growth of aerobic bacteria. Its application to wastewater may be very conditioned by the low solubility of the oxygen in the water.

- Anaerobic systems: In this case, the electron acceptor can be the CO2 or part of the organic matter itself, obtaining, as a product of this reduction, the carbon in its most reduced state, CH4. The use of this system has an important advantage, which is the obtaining of combustible gas.

- Anoxic systems: This refers to those systems in which the absence of O2 and the presence of NO3 make the latter the electron acceptor, transforming itself, among others, into N2, a completely inert element. It is therefore possible, in certain conditions, to achieve the biological elimination of nitrates (denitrification).

The most suitable type of biological process is chosen after analyzing the features of the effluent to be treated on a case by case basis.

Aerobic Systems

Aerobic wastewater treatment systems take advantage of the ability of microorganisms to grow by assimilating organic matter and nutrients (nitrogen and phosphorus) dissolved in the water in the presence of oxygen, which acts as an electron acceptor when oxidizing the organic matter.

This phenomenon leads to high energy yields and significant production of sludge, resulting from the high growth of bacteria under aerobic conditions.

AEROBIC TREATMENT STAGES

An aerobic treatment system consists of the following stages:

1. Pre-treatment

Large size solids arriving at the water treatment plant are first removed. If not disposed of effectively, these materials can lead to serious equipment failure. Stones, sand, tin cans, etc. cause significant wear on pipes as well as pumps.

Oils and fats are also removed at this stage to prevent the biological treatment from slowing down, as both the performance and the quality of the effluent decreases. Both physical and mechanical operations are used for this. The main operations used depend on the wastewater source, its quality and subsequent treatment:

- Separation of large solids: This system is used whenever the water to be treated may contain large solids. It consists of a pit at the collector entrance to concentrate the solids and decant the sand to a specific area where it can be extracted effectively.

- Gross filter: This operation prevents the massive arrival of large solids from obstructing later parts of the process. It consists of bars with different distances between them to separate the solids according to their size.

- Screening: This operation is required when wastewater contains large amounts of floating solids or debris. Sieves of different thickness are used.

- Desander: For removing solid particles larger than 200 microns which can block pipes or pumps and can scratch and damage different pieces of equipment.

- Degreasing: To remove grease, oils, foam and other floating materials lighter than water, which can affect subsequent treatment processes. This is normally done by blowing in air to demulsify and make the grease float.

2. Primary treatment

At this stage, suspended solids are removed from the water using different physical and chemical processes. These solids can be sedimentable, floating or colloidal.

- Sedimentation: Separation under gravity results in particles denser than water being deposited at the bottom of the settler. The greater the size and density of the particles to be separated in the water, the higher the sedimentation velocity, and this is the main design parameter for this equipment. This sedimentation operation is also known as decantation. Primary decantation removes suspended solids (60% approx.) and organic matter (30% approx.) and protects subsequent biological oxidation processes from the intrusion of inert, high density sludge. There are rectangular, circular and lamellar settlers that can be used.

- Flotation: This is based on a difference in densities and separates solid or liquid matter which is less dense than the fluid, where it rises to the surface. Air is used as a flotation agent and, depending on how it is introduced into the liquid, there are two flotation systems: Dissolved Air Flotation (DAF), which introduces air into the wastewater under a pressure of several atmospheres; and Induced Gas Flotation, where gas bubbles are produced via diffusers.

- Coagulation – Flocculation: If very small particles are present, highly stable colloidal suspensions are formed, due to the electrical interactions between them, and their sedimentation rate is slow. Thus, to improve their removal, chemical reagents are added to destabilize the colloidal suspension (coagulation) and promote their flocculation to obtain easily settleable particles. Coagulants are usually chemicals with an opposite electric charge in solution to the colloid.

- Filtration: The water is filtered through a porous medium to retain as much of the suspended material as possible. The porous medium traditionally used is a bed of sand of varying height.

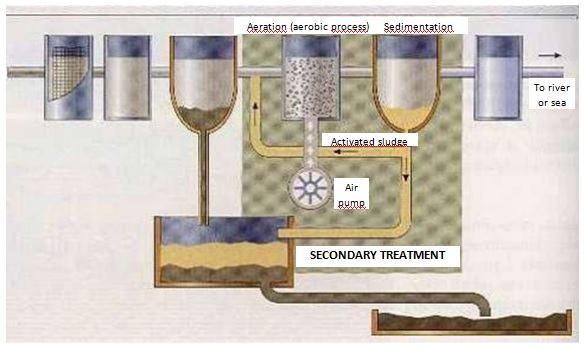

3. Secondary treatment

This is based on biological processes which use microorganisms (especially bacteria) to remove biodegradable organic matter, both colloidal and dissolved, and nutrients (compounds containing N and P). In most cases, organic matter is oxidized by the microorganisms which use it as a source of energy for growth.

Aerobic processes are based on the elimination of organic pollutants by their transformation into bacterial biomass with the help of oxygen (which acts as an electron acceptor in the oxidation process), CO2 and H2O.

- Digestion: In aerobic systems, wastewater passes through an aerobic reactor-digester containing the microorganisms which oxidize dissolved organic matter via an oxygen flow.

- Decantation: The sludge formed is separated by gravity in secondary settlers.

4. Tertiary treatment

Depending on the quality of the effluent obtained, its final destination and relevant legislation, tertiary treatment may be applied to remove residual organic load and other pollutants not removed after the secondary treatment, such as nutrients, phosphorus and nitrogen. Any combination of treatment processes can be used, whether physical, chemical or biological. Generally, they are:

- Filtration: Microfiltration, ultrafiltration.

- Ionic exchange.

- Reverse osmosis.

- Adsorption.

- Membranes.

- Disinfection. This consists of removing or inactivating pathogenic or any other living microorganisms to ensure the treated water can be reused. The main disinfection processes are:

- Chlorination

- Ozonation

- Electrodisinfection

Classification Of Aerobic Digestion Reactors

Depending on the system used for the growth of biomass, aerobic treatment systems are classified as follows:

1. Biomass in suspension (activated sludge). Biomass grows freely or in suspension inside the bioreactor and produces flocs.

- Conventional process

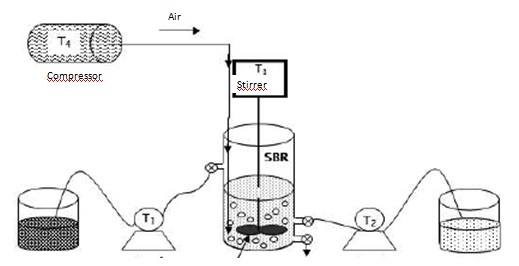

- Sequential Batch Reactors (SBR): This type of treatment is in batch form with all processes occurring in the same tank sequentially over time. It is a good alternative for those industries that have small effluents but with highly variable properties.

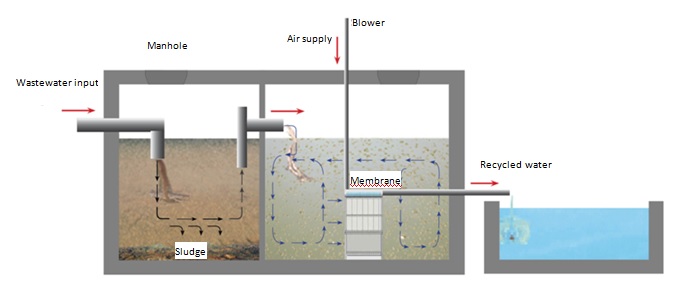

- Membrane Bioreactor (MBR): This is similar to the activated sludge method but with an ultrafiltration membrane module inside to separate the sludge and the liquid via membranes. This has significant advantages over traditional secondary decanters and is an alternative where there is little space.

Membrane bioreactors are the combination of a bioreactor, in which a concentrated suspension of microorganisms degrades the contamination present in the water, and a membrane filter unit (0.01-0.04 µm) that separates the biomass from the purified water.The main advantages of the MBR system compared to activated sludge is that it consists of relatively small installations that enable high quality effluent to be obtained with low production of slurry. This system is suitable for treating both urban waste water and biodegradable industrial waste water. The majority of the applications of this system are found in the food, pharmaceutical and cosmetics sectors and in dumpsites.

Another advantage is that it provides the freedom to control the process, as the hydraulic retention times and the biomass can be manipulated. As it does not function with sediment, the installation can be small and achieve a greater separation than the previous systems due to membrane technology. Although, at the same time, it generates more soiling than other systems as the medium is subject to a greater agitation compared to the conventional sludge system, which causes a greater production of EPS. Therefore, despite the series of positive characteristics mentioned, this technology involves high costs related to the prevention and disposal of the soiling in the membrane that guarantees it functions optimally.

The permeability of the membrane is influenced by the characteristics of the slurry. The cells, present in the slurry, can form a layer around the membrane during filtration, and form a biofilm that lessens the permeability, a problem that can be increased by the depositing of particles and the adsorption of colloidal materials. Biological factors, such as the presence of nutrients, the age of the slurry and the level of agitation affect the production of extracellular polymeric substances that are responsible for the soiling. The soiling of the bioreactor can be reversible, in other words, it can be eliminated by physical cleaning, or irreversible, in other words, requiring a chemical clean. This depends on how firmly the soiling binds to the membrane. However, there is also soiling that cannot be reversed, that cannot be removed by any means, which defines the useful life of the membrane. All of these types of soiling occur at different stages in time.

During filtering, the increase in trans-membrane pressure is principally due to the formation of the filter cake that obstructs the membrane. This may be eliminated with physical cleaning, but in the long term this cleaning is not able to resist the initial trans-membrane pressure. When the pressure after the physical cleaning exceeds a certain amount, a chemical clean is performed. Nevertheless, as a consequence of the non-reversible soiling, the chemical clean does not prevent the gradual increase in the trans-membrane pressure over a period of years.

The filter module may be external or internal to the bioreactor. The difference is that the energy consumption in the external MBR system is ten times higher than the internal energy consumption. Even so, external MBRs do have some advantages compared to internal MBRs, such as the possibility of cleaning the membrane in situ, easy access to the modules, the possibility of modifying the number of modules and optimizing the aeration of the bioreactor to obtain maximum oxygen transfer coefficients.

There is also a new configuration of MBRs called the Air lift MBR that consists of an external MBR, which provides easy access to the membrane and works with large flows. But, at the same time, the internal system also has its advantages in that it has a low energy consumption (0.5 kwh/m3).

- BIOCARB®: This is an exclusive process patented by Condorchem Envitech and is based on a fixed bed aerobic reactor with granular activated carbon as filler material. The carbon filters, adsorbs and acts as a support for the biofilm, in addition to feeding the microorganisms with minerals and trace elements. The adsorption process provides a double contribution to the process, by laminating the pollutant loading peaks and by increasing the residence time of the contaminants inside the reactor so the persistent organic compounds can break down. The BioCarb® reactor has proven especially effective in treating colored contaminants difficult to biodegrade. In addition, the immobilization of the biomass on the surface of the lignite carbon means the wastewater is biologically and physicochemically treated in a single stage.

2. Fixed biomass. The biomass grows attached to a natural or artificial support where it forms a layer or film.

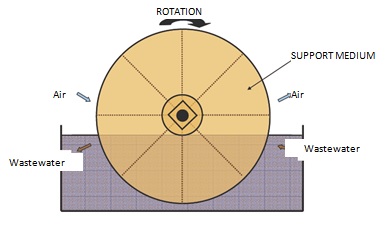

- Biodiscs: This consists of a set of discs of a certain material (e.g. wood, corrugated polyethylene or polystyrene and PVC) that revolve around a horizontal axis, located inside the reactor. A bacterial biomass film gradually forms on this medium, and uses the soluble organic matter in the wastewater as a substrate for its metabolism. When the surface of the disc is in contact with the air, the biomass attached to the disc takes the oxygen necessary for the degradation of the organic matter during the immersion period.

- Biofilters: The air is pulled near the source of emanation and led into a conditioning chamber, where it is saturated with moisture and directed to a fixed biomass bed. Contaminants are absorbed onto the biomass biofilm which forms on the filler and are subsequently digested by microorganisms. These digestion and metabolization processes convert the compounds into ones that no longer smell.

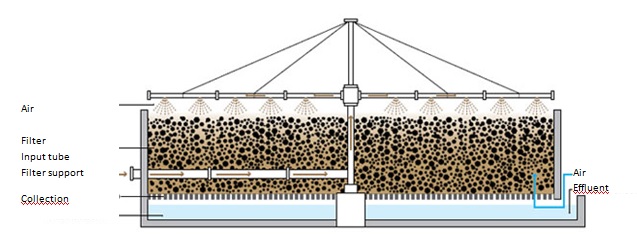

- Trickling filters: Wastewater flows or is sprayed onto the filter. As it passes through the filter pores, the organic matter is degraded by the biomass covering the filter material.

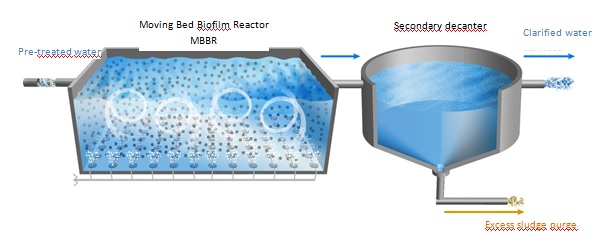

- Moving bed biofilm reactor (MBBR): The purifying bacterial culture is in the form of a biofilm adhered to specific large surface supports (filter fill) which are submerged and moving in the biological reactor.

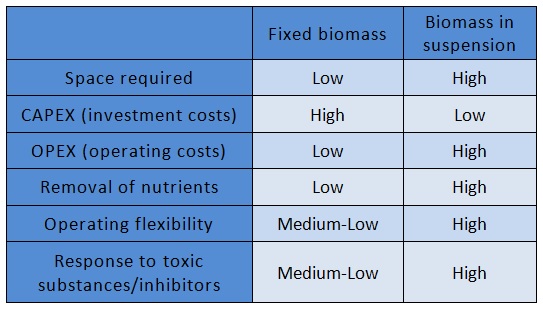

Selecting the most convenient biomass in suspension or fixed biomass biological process is done after analyzing the effluent properties, type of industrial process producing it, the degree of purification required and the global needs of the user:

Aerobic Vs Anaerobic Reactors: Advantages And Disadvantages, Basic Selection Criteria

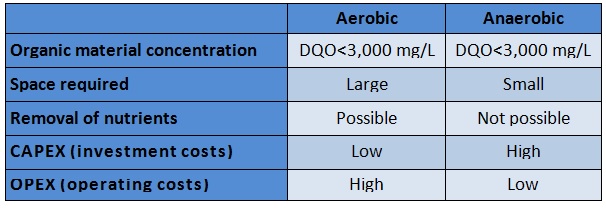

The criteria used to select whether an aerobic process is more appropriate or if an anaerobic process is preferable are:

- Concentration of organic matter to be removed.

- If nitrogen removal is necessary.

- Availability of physical space.

- Project OPEX and CAPEX costs.

The following table shows which kind of process (aerobic or anaerobic) is preferred according to these criteria:

Advantages of Aerobic systems:

- A wide variety of wastewater can be treated: the two requirements are they must be biodegradable.

- Higher yield than anaerobic = 0.4 (1g of organic matter for 0.4g of biomass).

- Ease of operation.

- Low CAPEX.

- Minimizes production of odors.

- Reduces coliforms, pathogens and fats.

- Produces clarified supernatant.

- A greater number of bacteria types can be used for digestion.

- Lesser sludge respiration rate.

Disadvantages of Aerobic systems:

- High OPEX due to continuous energy expenditure associated with aeration.

- Many parameters to control for optimum results: pH, Temperature, % Organic matter, Inlet flow, % toxic compounds (biocides).

- Higher costs during maintenance or breakdown, due to having to maintain the organic matter levels necessary for the microorganisms to survive.

SLUDGE PRODUCED: CHALLENGE OF AEROBIC SYSTEMS

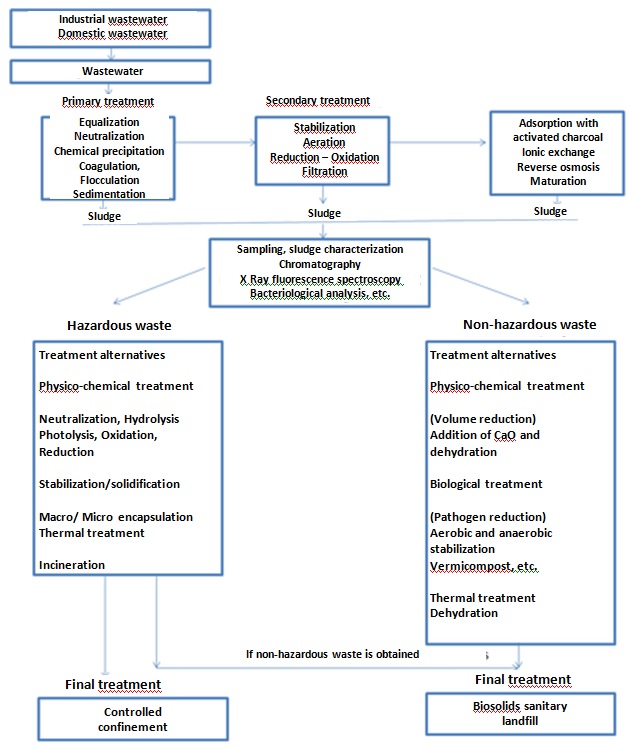

One of the biggest challenges of aerobic systems is the management of the sludge produced. The following diagram shows the general sludge management process, depending on the amount.

Currently, anaerobic treatment is used for sludge management after aerobic treatment in many cases and whenever possible.