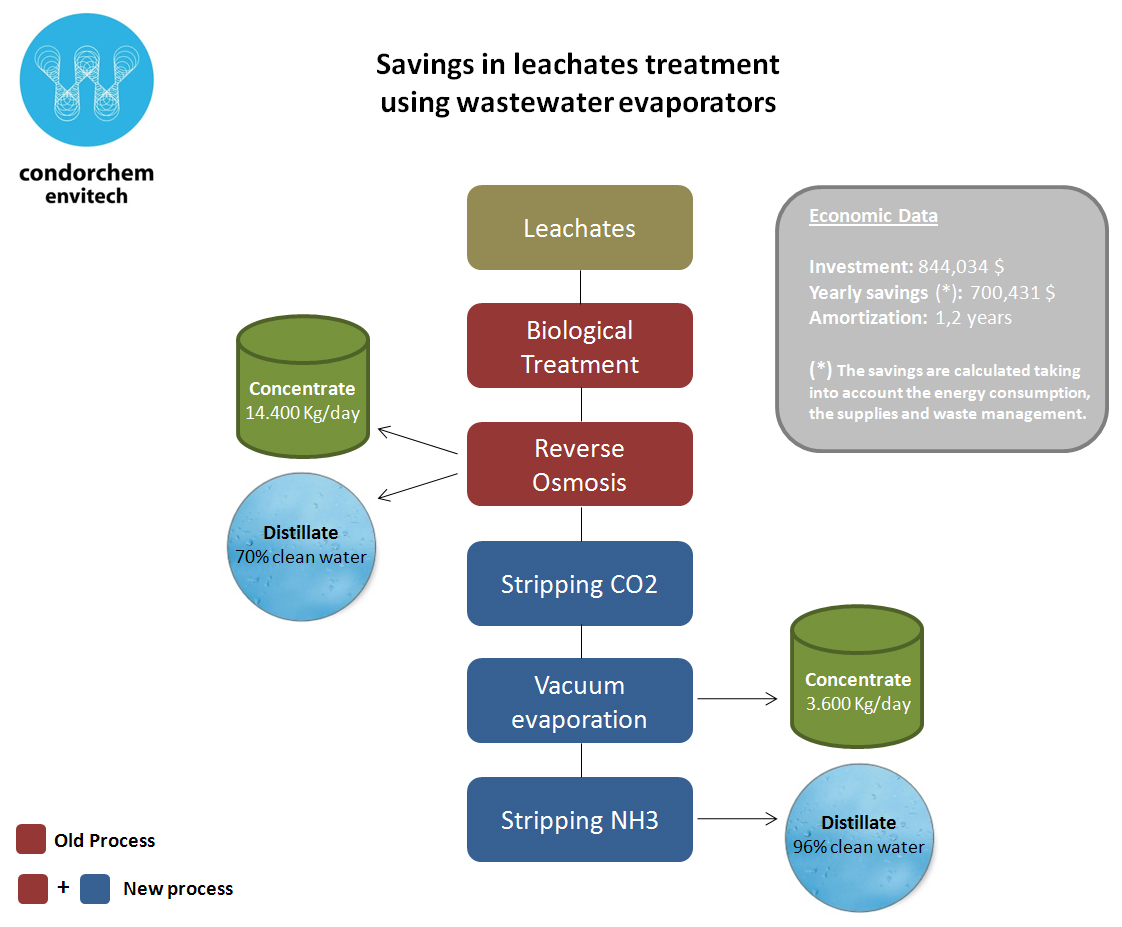

Landfill leachate treatment processes

- An old process that combines biological treatment with a reverse osmosis (red).

- A new process that adds a vacuum evaporation stage and a stripping stage to the old process (red and blue).

The results of the new process are substantially better thanks to the great performance of the wastewater evaporator, specially in the following points:

- It recovers a much larger amount of clean water that can be discharged in compliance with the regulations.

- The concentrate of waste is much smaller.

- Having a smaller concentrate of waste implies very important savings in the management of such waste.

We can also see that the investment required for the installation of the new process is amortized in just 1 year and 2 months and the landfill can benefit from huge cost savings from that point on.

The following graphics shows two landfill leachate treatment processes: